To avoid pollution from diesel exhaust, Danfoss does this......

Reengineering workshop

In order to avoid damage to critical systems due to long-term shutdown, the ship needs to be "hot" parked, that is, the diesel engine needs to be kept warm, and the electronic control and ventilation system needs to be kept running. Initially, ships were powered by moored generators on board. But this is not a satisfactory solution.

Because diesel exhaust will cause pollution, but also will produce lasting noise. In addition, high-quality marine diesel and generator set maintenance costs are very high: in terms of generator set maintenance alone, oil and filters need to be replaced every 1,000 hours, and a required overhaul every 20,000 hours. Moreover, according to the statutory requirements, a crew of 6 to 8 is also required to maintain the operation of the ship. The shore point scheme is a good solution to the above problems.

Shore Power Scheme

The shore power solution, which uses shore power to power ships, was proposed as a business case by Karl Jeppesen, head of the electrical department of Maersk Supply Service, in early 2017, and the shore power solution, which uses shore power to power ships, is expected to achieve a return on investment within six months. Soon, the company passed the shore power project, and the whole system was fully operational by October 2017.

Well tested and trustworthy

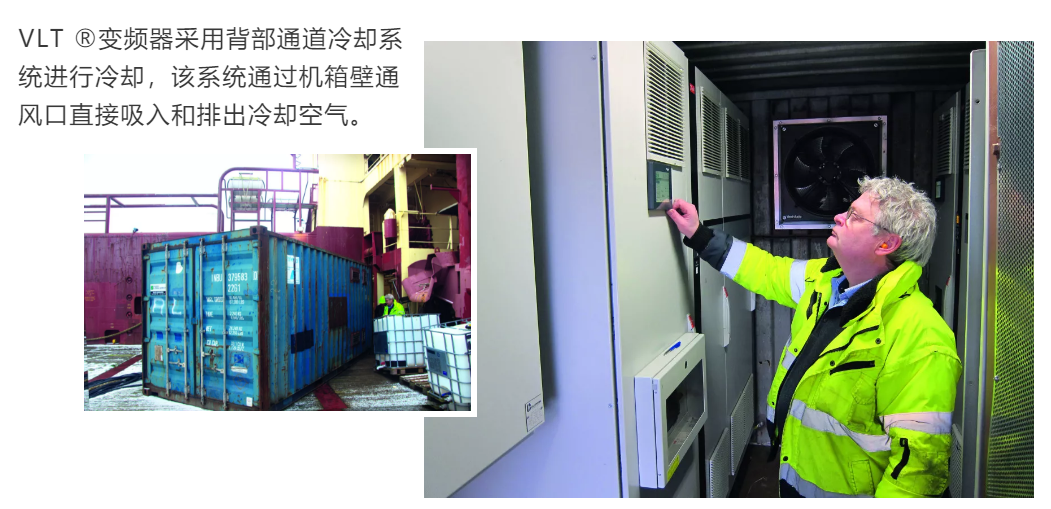

Maersk Supply Service have used a number of Danfoss inverters on their ships, and Karl Jeppesen has also used Danfoss VLTs for many years.?The converter has refurbished many ships' deck machinery, propellers, cooling water pumps and engine room ventilation systems. In the heavy load and harsh environment on a global scale, these inverter products have proved to have extremely reliable performance, so it is logical to become the first choice for the shore-based power supply system.

Flexible Partners

The system topology is designed by Danfoss Drives, while the chassis, switchgear and system integration are manufactured and installed by Caverion companies according to the specifications proposed by Karl Jeppesen. The project also involved close cooperation with the power company Trefor, which installed a transformer from 10 kV to 450 V (maximum power 1800 A) at the terminal. This requires some costly civil engineering to install hundreds of meters of 10 kV underground cables connected to the transformer. According to an agreement between the Maersk Supply Service and TreFor, electrical energy is purchased directly from TreFor.

Higher overall efficiency

The new shore power scheme has greatly reduced the workload and maintenance work, and now only requires two engineers/electricians and a kitchen assistant crew. The impact of noise on the port environment is almost negligible, and the pollution of diesel exhaust gas to the local environment is completely avoided. There are also benefits at a higher level: all the electricity needed to run the system comes from the Danish national grid, 40% of which comes from renewable sources.

The ship's seawater cooling pump and engine room ventilation system are driven by Danfoss frequency converters

Cost recovery time

To prevent water pipes and equipment from freezing due to low temperatures, ships consume twice as much power in winter as in summer. After four seasons of operation, the business case proves that the project can pay for itself within 5 months, which is shorter than expected.

Further explore the potential of the ship

A 50 to 60Hz converter is installed on the deck of one ship, and the converter output is connected to the shore-based power supply access point of another ship through a 440V,60Hz cable.

2 x 450 kW VLT in converter?AutomationDrive FC 302 inverters, each equipped with a sine wave filter and a transformer for galvanic isolation. A total of 12 x 250 A output circuit breakers can provide power supply for 12 ships. The system will monitor the energy output to each ship. Once the power consumption of any ship is abnormal, the problem can be quickly found and dealt.